AI-based detection of cracks in railway sleepers

Trains can only run reliably and on time if the infrastructure – especially the rails – remains undamaged. Maintenance is therefore an essential task for railway companies, including inspecting the sleepers for cracks. Within the route network of DB Infra, one of Deutsche Bahn’s railway infrastructure companies, more than 62 million prestressed concrete sleepers have been laid, all of which must be regularly inspected.

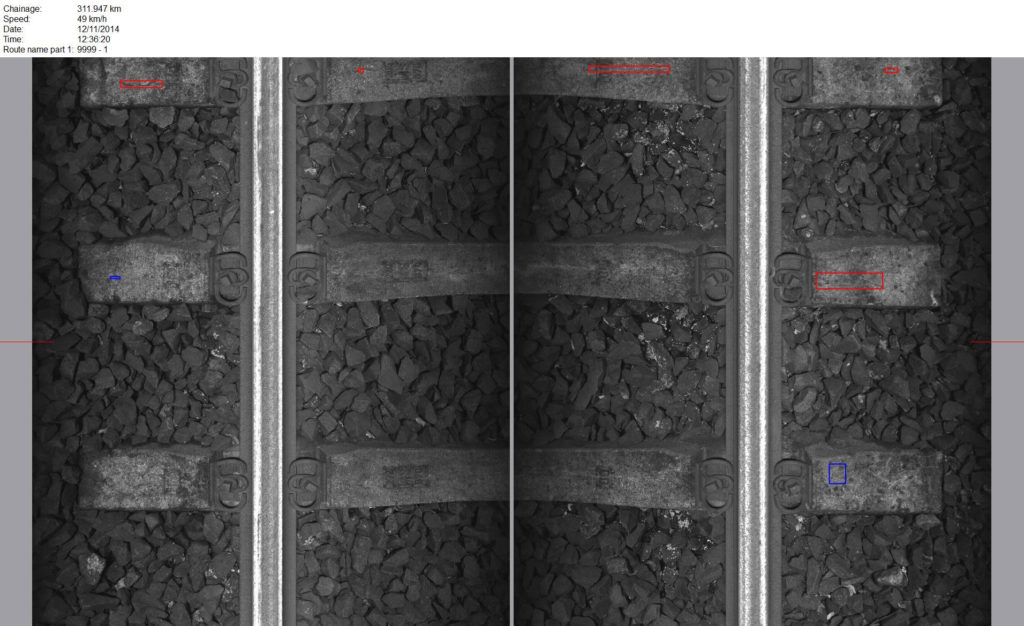

DLR is supporting Deutsche Bahn in rail sleeper inspection with software that employs artificial intelligence (AI). At the DLR stand, researchers are demonstrating the software in action, displaying sample sleepers on a screen.

DB InfraGo operates a measurement train that photographs the track bed at speeds of up to 140 kilometres per hour. Using digital image processing, the company can detect cracks in railway sleepers. However, due to the high variability of visual features in the track bed, traditional image processing is prone to errors – for example, detecting cracks were none exist. These messages then have to be reviewed by employees to distinguish actual cracks from branches, dirt and other similar errors. This process is time-consuming and expensive.

DLR’s rail sleeper inspection software uses state-of-the-art machine learning algorithms, specifically a process known as deep learning with convolutional neural networks (CNN). These algorithms promise high detection accuracy, making them ideal for the automated identification of cracks. One particular advantage of the software is that it learns from manual corrections, continuously improving its detection accuracy over time. Visitors can use this exhibit to familiarise themselves with the software’s user interface and learn about its development, which also encompasses the quality assurance procedures and processes for routine operations.

Link:

German Aerospace Center (DLR)

Institute of Transportation Systems

E-Mail contact-dlr@DLR.de