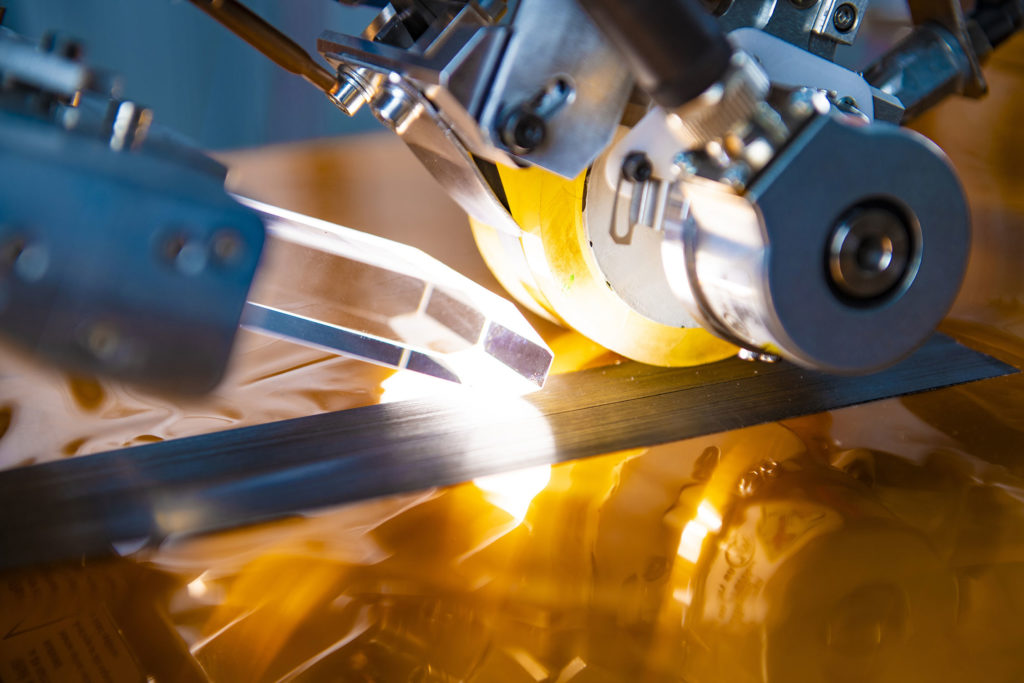

Flash-lamp based in-situ automated fiber placement of thermoplastic composites

Additive manufacturing of thermoplastic composites

Thermoplastic composites are of major interest for various aerospace applications due to the opportunities they offer regarding effective production and weldability, compared to thermoset composites. Automated fiber placement (AFP) may render high performance thermoplastics cost effective. Especially in-situ processing of tapes as a one step additive manufacturing technology on a formative tool. Recent technological advances in heating systems, robot-based end-effectors and available materials like LM-PAEK have spurred research activities regarding in-situ AFP. The industrialization of the process is a major aspect of the research since it is crucial for future application.

Innovative Heat-Source for a flexible Production

Therefore, the ZLP AU investigates flashlamp heating for in-situ AFP, that provides high energy density of incoherent light in the UV-, visible- and infrared-spectrum. Compared to laser radiation this is less harmful and makes laser protection housing obsolete. Without peripheral safety appliances, opportunities for a flexible and effective production emerge, e.g. the production of very large components.

Co-Development with DLR Stuttgart

The performance of flashlamp in-situ AFP is benchmarked against laser based in-situ AFP, an established and well-defined process at the institutes’ site in Stuttgart. Thus the highly transient process involving heating, consolidation and cooling within a short timeframe, in combination with various production parameters is thoroughly investigated and safeguarded for industrial use.

Inline Quality Assurance

Integrated quality assurance (QA) of both the placement accuracy and proper heat treatment enable reproducible processing. Gaps, misplacements and other defects are detected, assessed and ideally corrected on sight.

Future Application: Large Aerospace components

Conclusively, the combination of materials with excellent mechanical properties and a flexible, yet robust production render in-situ AFP processing suitable for a wide range of aerospace applications such as aircraft fuselages, fairings and tanks.