Power-to-heat and heat storage for industrial processes

The decarbonisation of natural gas-fired industrial processes and rising costs of fossil energy sources require new technologies to generate high and ultra-high-temperature heat from renewable energy. Novel power-to-heat technologies combined with thermal energy storage offer opportunities for a heat supply that is both emission free and highly flexible to operate.

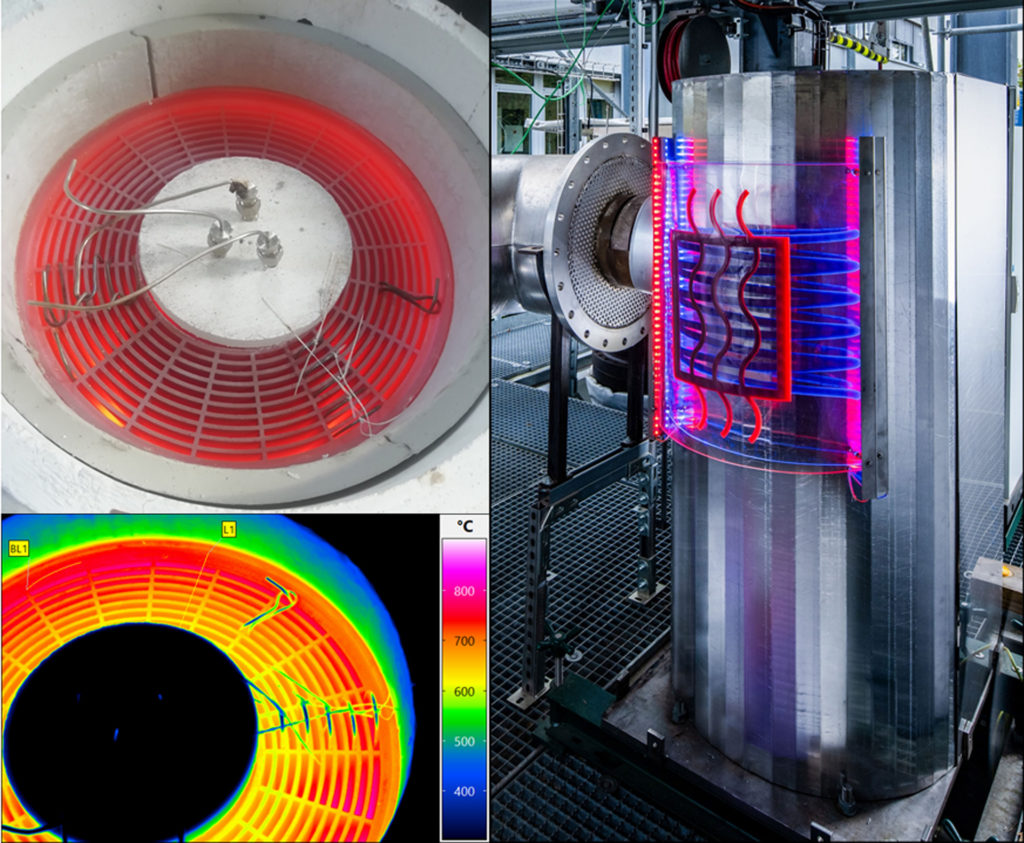

The DLR Institute of Engineering Thermodynamics is developing solutions for resistance and induction heating to be used with sensitive, latent and thermo-chemical heat storage technologies. Work is targeted to maximise power density and cost-effectiveness and includes qualification on a ‘pilot scale’.

At Hannover Messe 2024, DLR is presenting an electric, high-temperature heating system. It is based on electromagnetic induction and can heat gaseous media for a wide range of industrial applications. The core elements of this heating system consist of inductively heated, electrically conductive ceramics with large heat-transferring surfaces. In contrast to available technologies, temperatures of up to 1200 degrees Celsius can be reached without compromising on service life. Heat can then be generated on the scale of megawatts all without contact, combined with great freedom in the design of the processes. There are also advantages in terms of the achievable power density, which is up to four times that of metallic heating elements.

Ceramic-based inductive air heaters have the potential to cost-effectively replace natural gas burners, for example in the chemical, cement, ceramics and steel industries. Due to high maximum temperatures, it is even possible to fulfil application requirements that were previously only achievable with hydrogen burners – and at lower costs.

Link:

German Aerospace Center (DLR)

Institute of Engineering Thermodynamics,

DLR – Institute of Engineering Thermodynamics

E-Mail contact-dlr@DLR.de