HLFC HTP Leading Edge Demo

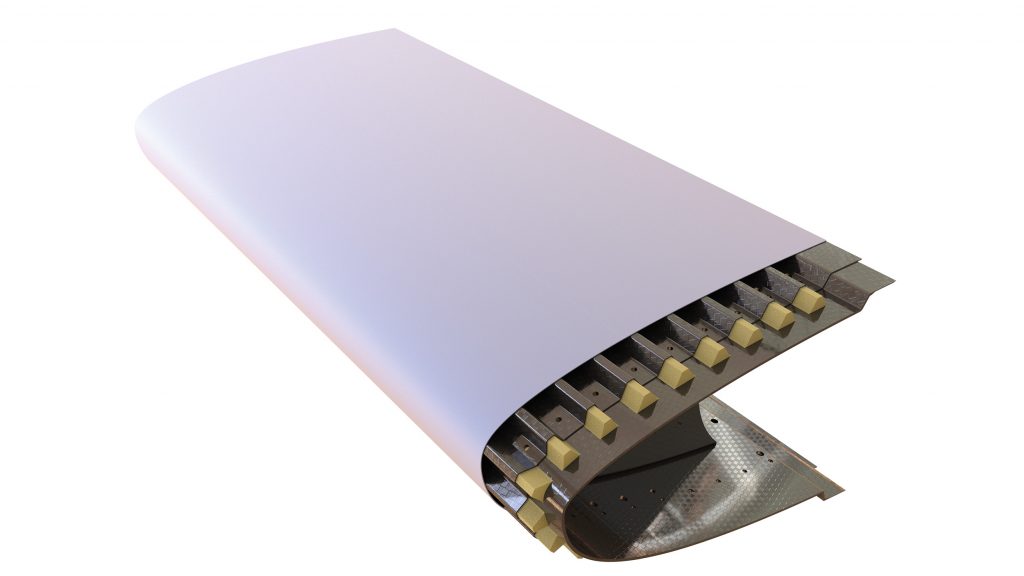

Horizontal stabiliser leading edge with integrated extraction

New commercial aircraft need to use even less kerosene. This can be achieved by low-drag laminar flow. Achieving laminar flow even at high airspeeds requires the combination of a laminar flow wing body with a leading edge that controls the flow using suction to keep the airflow laminar. This combination is called a Hybrid Laminar Flow Control (HLFC) wing.

Although the physics of laminar flow is well understood and predictable, its introduction into production aircraft has not occurred due to the complexity of the systems required for an HLFC wing. As part of the EU/ Horizon 2020 / CleanSky 2 initiative, a consortium of Airbus, the Spanish supplier Aernnova, and DLR has been formed with the aim of implementing a mass-producible HLFC horizontal tailplane.

The aim is to fnd a compromise between low production costs and weight, as well as aerodynamic effciency, in a project supported by the EU and led by Airbus that will present a business case for the design. The system components (for example, pumps and pipelines) must also be implemented in compliance with aviation certifcation requirements.

Despite the high standards and tight constraints, an implementation strategy was developed that proved to be promising in all aspects. The integration of innovative pumps and the combination of the structure with the necessary control systems for extraction through the microporous erosion protection layer were the keys to success. With the H²LED structural and functional demonstrator, numerous uncertainties in the design could be eliminated. This has led to a horizontal tailplane leading edge that can be mounted on an Airbus A350.

The transfer of this concept to the wings within the EU / Horizon 2020 / CleanSky 2 initiative has begun, because a laminar flow wing can achieve much greater kerosene savings.

German Aerospace Center (DLR)

Markus Kleineberg · E-Mail: markus.kleineberg@dlr.de · DLR.de/en