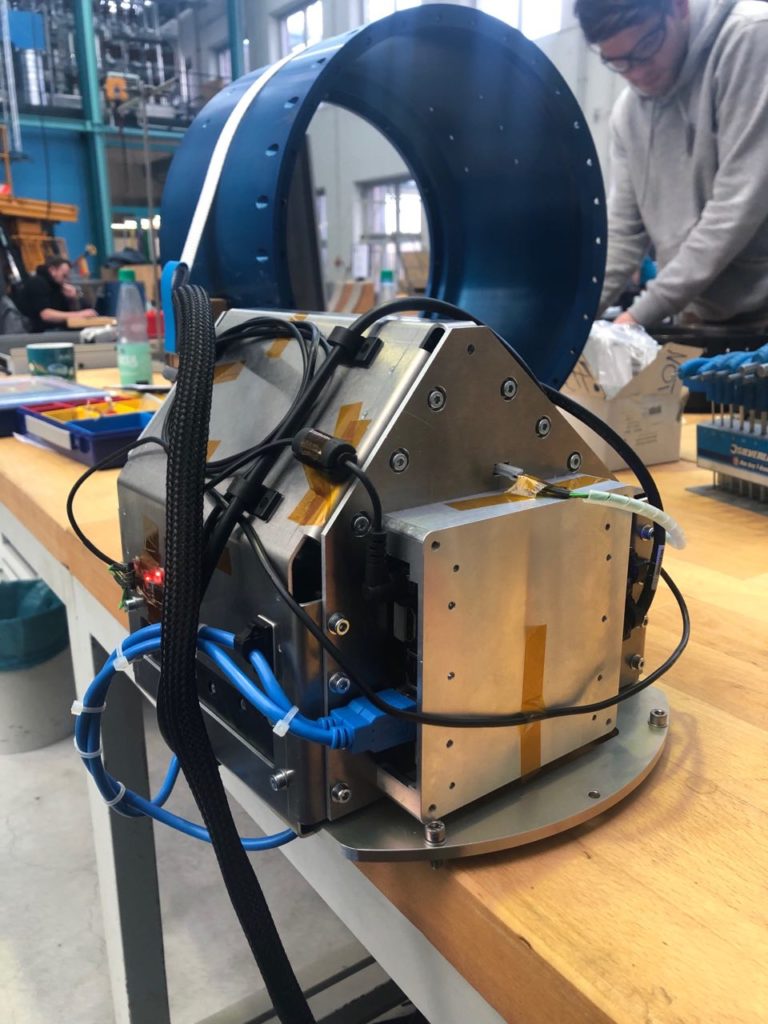

ADDONISS Prototype

Aging and degenerative diseases of neurons on the ISS

ADDONISS is an experiment by students of the WARR space labs team at TU Munich. In December 2021, it became a winning project of the “Überflieger 2” competition of DLR and LSA. The competition allows the three German and the Luxembourgian winning teams to conduct an experiment on the International Space Station ISS.

ADDONISS stands for “Aging and degenerative diseases of neurons on the ISS” and will observe a total of six neuronal cell cultures in microgravity. A special focus will be on signs of cell aging, since aging processes occur differently in microgravity than on Earth.

The experiment will be operated on the ISS for over a month in a fully automated 2U CubeLab unit from Space Tango. Using so-called Micro Electrode Arrays (MEAs), ADDONISS will measure the evolution of electrical signals from brain cells in microgravity. Often, biological experiments in spaceflight have to be chemically fixed or frozen in order to be analyzed later on Earth. However, continuous monitoring of the cells aboard the ISS using the MEAs allows measurements to be made directly on site without human intervention.

ADDONISS includes several subsystems for cell life support and data collection. For example, a heating system to keep the cells at body temperature and various sensors to monitor the system. Furthermore, a fully automated pumping system that regularly supplies the cells with fresh culture medium. Half of the cell cultures receive a medium with added beta-amyloid, a protein that is a hallmark of Alzheimer’s disease.

The experiment should not only provide information about the effects of space travel on humans, but at the same time open up new possibilities for research into degenerative diseases on Earth.

Link:

WARR

WARR space labs

Fanny Rößler · Email fanny.roessler@warr.de

Student 3D printed combustion chamber Prototype

Using state of the art technology for bi-liquid propelled suborbital rockets

Through the application of additive manufacturing, a student group at the Technical University of Munich is bringing bi-liquid rocket propulsion closer to the next generation of space enthusiasts. Project Nixus is the name of the newest project of the rocketry team of the Scientific Workgroup for Rocketry and Spaceflight (Wissenschaftliche Arbeitsgemeinschaft für Raketentechnik und Raumfahrt, WARR e.V.), in which the team of 80 students aims to compete in international rocketry competitions with their 4.5 meter sounding rocket.

Project Nixus builds on past experience from the preceding Project Cryosphere, which is completing development of the 10 kN EX-3 hybrid sounding rocket intended for 35 km, exceeding the European amateur rocketry altitude record. Most notably, within this project the students were able to gain extensive experience working with cryogenic liquid oxygen. Project Nixus will now expand on this knowledge with the addition of Ethanol as liquid fuel to replace the solid HTPB of Project Cryosphere.

In particular at this small scale, increases in system complexity are very taxing on rocket performance. Through cooperation with TUM research institutes and industry, the team capitalises and expands on the advances in additive manufacturing with the goal of enabling the educational experience of bi-liquid propulsion, while still building a competitive rocket.

On display at the ILA is a 3d-printed model of a possible integrated injection manifold of the Project Nixus EX-4 rocket. The manifold incorporates the injection elements, optimised fuel and oxidiser distribution manifolds, interfaces, and cooling channel collection into a single part. The print is executed in translucent resin to showcase internal pathways. A conventionally manufactured sub-scale version has already made its way onto test site for validation testing.

With the print of the full-scale chamber the team will push our current knowledge of additive manufactured Inconel behaviour to the edge and beyond. The work enables research into manufacturing of large precision thin-walled structures and material behaviour at extreme temperatures from cryogenic liquid oxygen to persistent exposure to over 3000 K hot combustion gases.

Furthermore, the team is delving into the field of fluid component design, utilising the many new degrees of freedom of additive manufacturing in order to innovate new lightweight valve designs.

Link:

WARR

WARR Rocketry

Francesco Longhetti · E-Mail Francesco.longhetti@warr.de

ELVIS – Exploration of Low-Velocity collisions In Saturns rings

ELVIS is a high-altitude research experiment that was developed by ERIG e.V. in order to participate in the REXUS-BEXUS programme by DLR, ESA and SNSA in 2018. REXUS-BEXUS is a programme that gives university students the opportunity to develop a high-altitude experiment in close cooperation with professionals from several space agencies thus benefiting from their know-how and their experiences of working in space missions. Towards the end of the programme the developed experiments are launched on a sounding rocket at the ESRANGE space center in Kiruna, northern Sweden. The rocket reaches an altitude of 80 to 100 km. The flight has several phases which provide different environments for performing onboard experiments, e.g. a high acceleration phase during and after lift-off or the reentry phase after the apogee was reached. Furthermore, an approximately 3-minutes-lasting microgravity environment is given during the descend phase of the rocket.

The purpose of the ELVIS experiment is an improved understanding of the collision behavior of ice particles in the rings of the planet Saturn. For this reason, in its center ELVIS houses a chamber that contains small glass spheres which resemble the ice particles. Exploiting the microgravity phase during the rocket flight, the collison behavior of the particles is simulated by the glass spheres. The whole process is observed and recorded by multiple cameras for later evaluation on the ground.

The development of ELVIS was done by students of the student initiative ERIG e.V. in close cooperation with the Institute of Geophysics and extraterrestrial Physics (IGEP) of TU Braunschweig and supervised by the REXUS-BEXUS board. For developing a computer simulation of the experiment the team additionally cooperated with the Max Planck Institute for Dynamics and Self-Organisation.

Lennart Fox · E-Mail lennart.fox@er-ig.de

Schwerdtlein – Experimentalrakete Schwerdtlein

Die Experimentalrakete Schwerdtlein wurde von der ERIG im Rahmen des Projektes STERN (STudentische ExperimentalRaketeN) entwickelt. Das STERN-Projekt wurde vom DLR imitiert um Studierenden die Möglichkeit zu geben ihre eigene Experimentalrakete zu bauen und dann auf ESRANGE in Kiruna zu starten. Hierbei durchlaufen die Studierenden alle Phasen eines typischen Raumfahrtprojektes und bekommen in Reviews, die vom das DLR durchgeführt werden, Feedback zu ihrer Entwicklung. Von 2017 an hat die ERIG eine Experimentalrakete mit einem Hybridraketenantrieb entwickelt.

Der Hybridraketenantrieb, der das Herzstück der Rakete werden sollte, nutzte Distickstoffmonoxid (N2O) als Oxidator und Hydroxyl-terminiertes Polybutadien (HTPB) als Brennstoff. Alle Komponenten des Antriebsstrang wurden Leichtbauoptimiert, so hatte das Triebwerk eine Hülle aus CFK. Nach erfolgreichen Bodentests des Triebwerkes musst aus Zeitlichen- und Projektmanagementgründen die weitere Entwicklung des Hybridraketenantriebs eingestellt werden. Stattdessen wurde ein zugekaufter M1800Feststoffraketenantrieb für den Flug in ESRANGE genutzt.

Das Bergungssystem war eine Weiterentwicklung einer vorherigen, sehr erfolgreichen, Experimentalrakete der ERIG, der Enceladus. Das Bergungssystem war ein zweistufiges Fallschirmsystem, mit einem Drogue-Fallschirm der im Apogäum ausgeschmissen wurde und einem Haupt-Fallschirm der erst in niedriger Höhe ausgeworfen wurde, um die Rakete auf die letztendliche Landegeschwindigkeit abzubremsen. Für das Elektroniksystem, welches neben der Erkennung des Apogäums für den Fallschirmauswurf, auch Flugdaten aufzeichnet, wurden kommerziell erhältliche Altimeter genutzt. Zusätzlich waren Kameras in der Rakete verbaut um den Flug der Rakete zu filmen. Die Struktur der Rakete bestand aus CFK- und GFK-Rohren mit Verbindungsringen aus Aluminium. Alle Komponenten der Struktur wurden in der ERIG gefertigt. Schwerdtlein hatte einen Durchmesser von 143mm bei einer Länge von 2,1m. Mit dem Feststoffraketenantrieb wog Schwerdtlein 19kg und sollte ein Apogäum von 5,3km erreichen. Schwerdtlein wurde Ende 2020 in Esrange gestartet. Die Rakete erreichte ein Apogäum von 4,88km. Das Apogäum wurde von dem Elektroniksystem erkannt, leider kam es aber zu einer Fehlfunktion in dem Auswurfmechanismus des Drogue-Fallschirms. Dadurch wurde der Drogue-Fallschirm nicht ausgeworfen und die Rakete stützte ungebremst ab.

Florian Kreissig · Email florian.kreissig@er-ig.de