The EmpowerAX demo part – additive functionalisation of a multi-curved shell

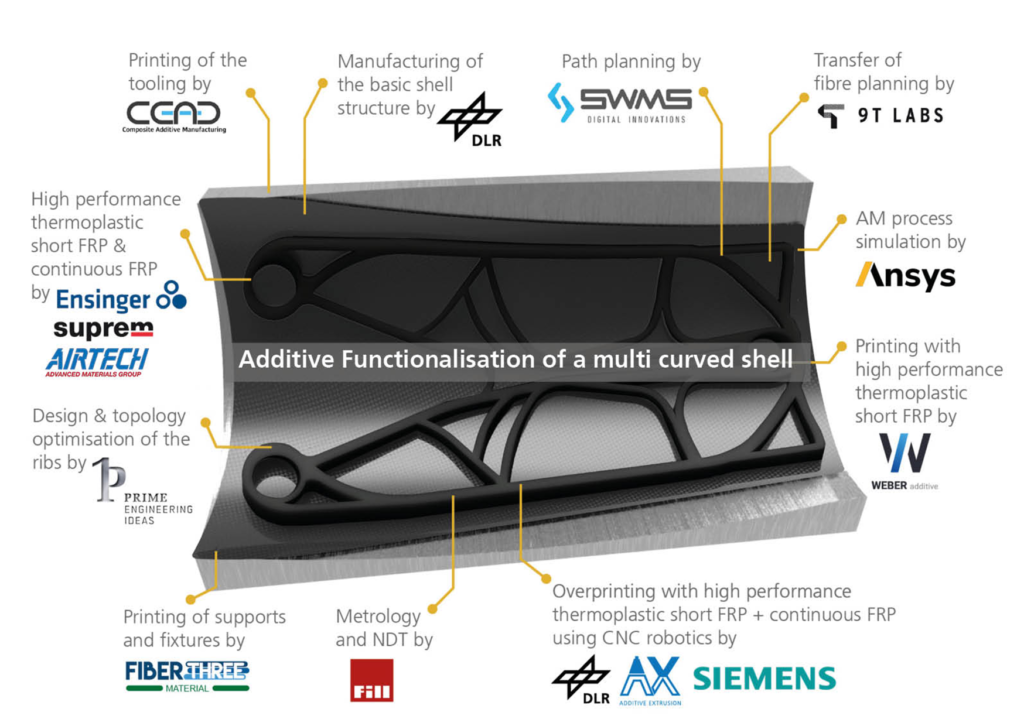

The EmpowerAX Demo Part exhibit is a joint project in the DLR Innovation Lab ‘EmpowerAX’. Leading industrial companies and research institutions have joined forces to demonstrate how a thermoset, multi-curved shell can be printed over with high-performance short and continuous fibre-reinforced thermoplastics. The entire process including the topology-optimised design, path planning, process simulation, printing and quality assurance will be carried out by DLR and 12 international industrial partners.

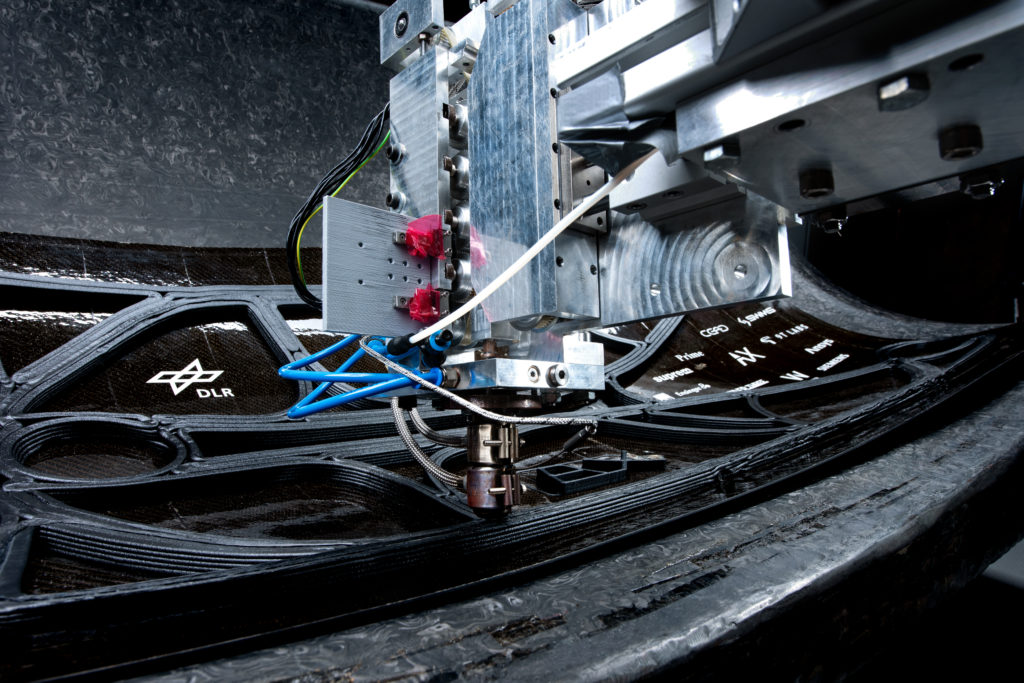

The basis of the EmpowerAX demonstration is a multi-curved shell structure measuring one square metre. It was produced through a conventional resin infusion process using a quasi-isotropic woven carbon fibre stack and an aerospace-grade epoxy resin cured at 180 degrees Celsius. The shell was coated by DLR with a thermoplastic PEI surface layer, which was applied directly in the infusion and curing process and bonded to the component to enable direct ‘over-printing’. The basic structure is derived from an aviation application. Landing with speeds of around 360 kilometres per hour, with simultaneous front and side winds, was the assumed design requirement. For this multi-curved shell to withstand the demands of its final usage, local stiffening is required.

This is done with the help of a ribbed structure designed for the required load, which is then applied using robot-assisted 3D printing with short-fibre-reinforced high-performance thermoplastic (SFRP). This is then stiffened at certain points with a continuous fibre-reinforced high-performance thermoplastic (CFRP).

The aim of the EmpowerAX demo component is to demonstrate the concept of additive functionalisation and the industrially available process chain. In addition, the component demonstrates the possibility of combining thermoset and thermoplastic matrices as well as short and continuous fibre-reinforced materials to optimise performance.

Links:

German Aerospace Center (DLR)

Institute of Lightweight System

E-Mail contact-dlr@DLR.de