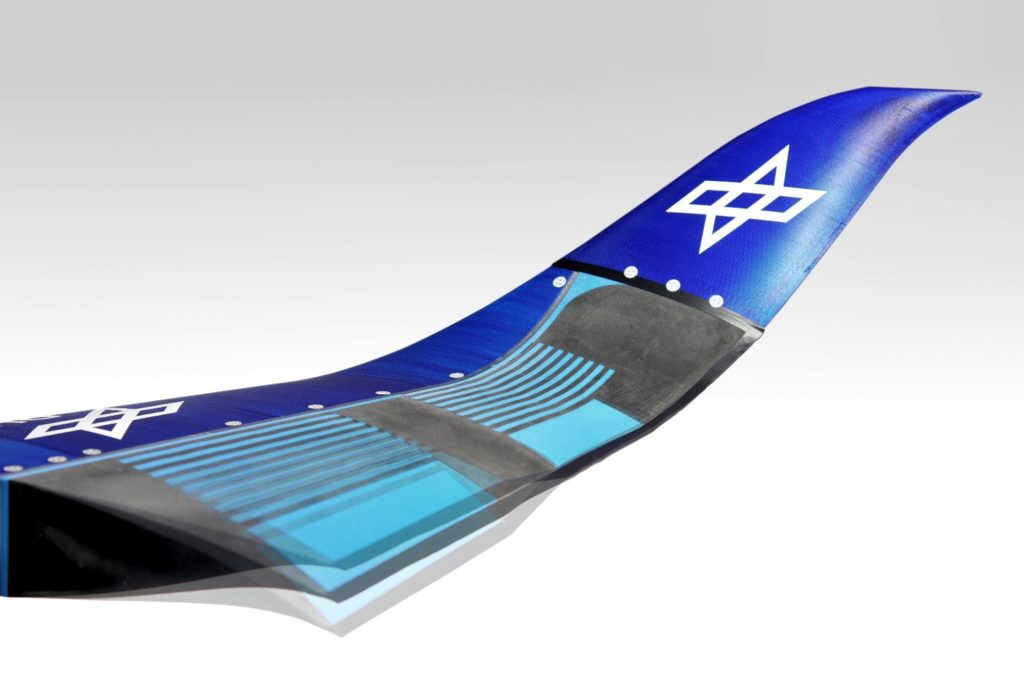

A 3D-printed trailing edge inspired by sea anemones

The DLR Institute of Composite Structures and Adaptive Systems has manufactured a morphing wing demonstrator using a Stratasys PolyJet 3D printer. Additive manufacturing has allowed for fast design iterations: the speed with which knowledge is obtained has allowed the research team to go directly from idea to experiment. Research in this topic is ongoing in EU and German projects that address implementation challenges in aircraft.

Morphing wings allow aircraft to adapt their shapes to particular flight operating points, with the potential to increase fuel efficiency. The seemingly contradictory challenge is to create a structure that is flexible enough to change shape yet stiff enough to resist external loads.

The showcased concept, called Fluid Actuated Morphing Unit Structures (FAMoUS), has been inspired by the structural behaviour of hydrostatic skeletons found in nature, such as those of sea anemones. The concept involves repeating reinforced elastomeric fluid-filled units or ‘cells’ that, under fluid pressure, allow wings to elongate, bend and twist. The highly distributed actuation and tight integration with wing skin and substructure make this concept attractive for volume-restricted applications such as in slender wings with tight spaces.

German Aerospace Center (DLR)

Institute of Composite Structures and Adaptive Systems

Dr. Srinivas Vasista · E-Mail: srinivas.vasista@dlr.de · DLR.de