According to figures from the organiser, the JEC Group, JECWorld is the leading international trade fair focusing on composite materials and their applications, with some 43,000 visitors (2018 data). JECWorld is held every spring in Paris. Seventy-three percent of visitors come from Europe. Alongside France and Italy, Germany is strongly represented, ranking second among the 115 guest countries with over 280 exhibitors. In addition, the Asia-Pacific region and North and South America are well represented at JECWorld. Thirty-three percent of trade visitors are from the aviation industry, followed by 26 percent from the automotive industry and road-based transport in general.

News

News 12

Thursday, 14 March 2019 | Virtual Aircraft Maintenance

Maria Moix-Bonet from the DLR Institute of Composite Structures and Adaptive Systems demonstrates the possibility of future aircraft maintenance based on augmented reality, remote collaboration and a decentralised database (digital twin), using the Airbrake as an example.

News 7

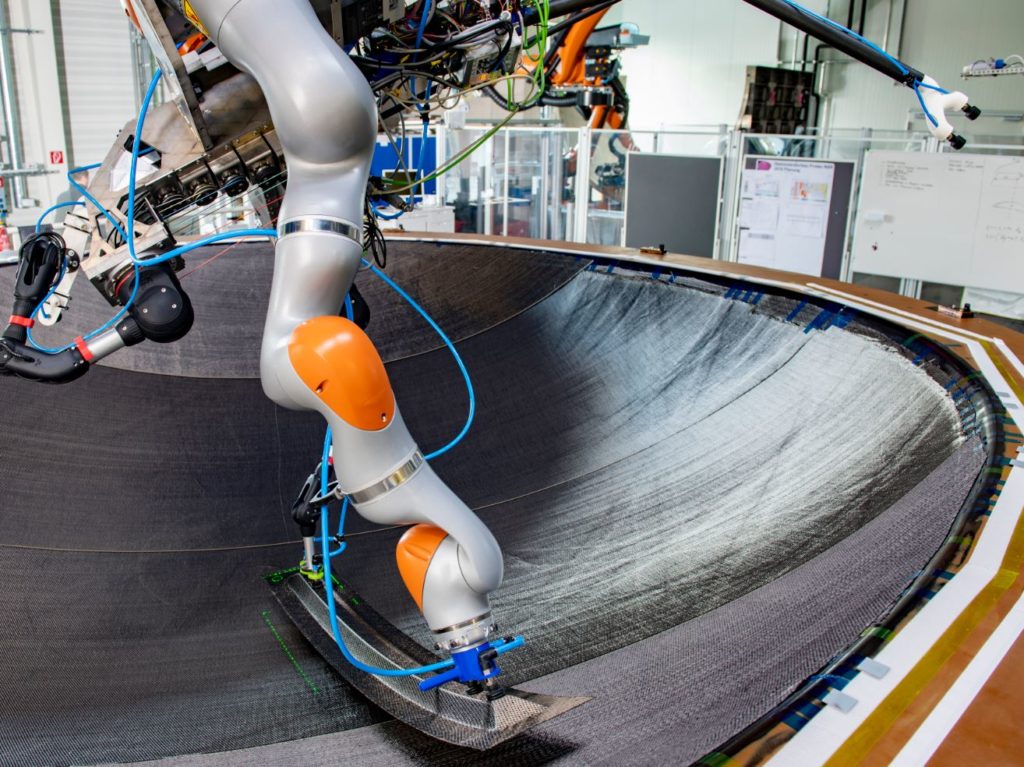

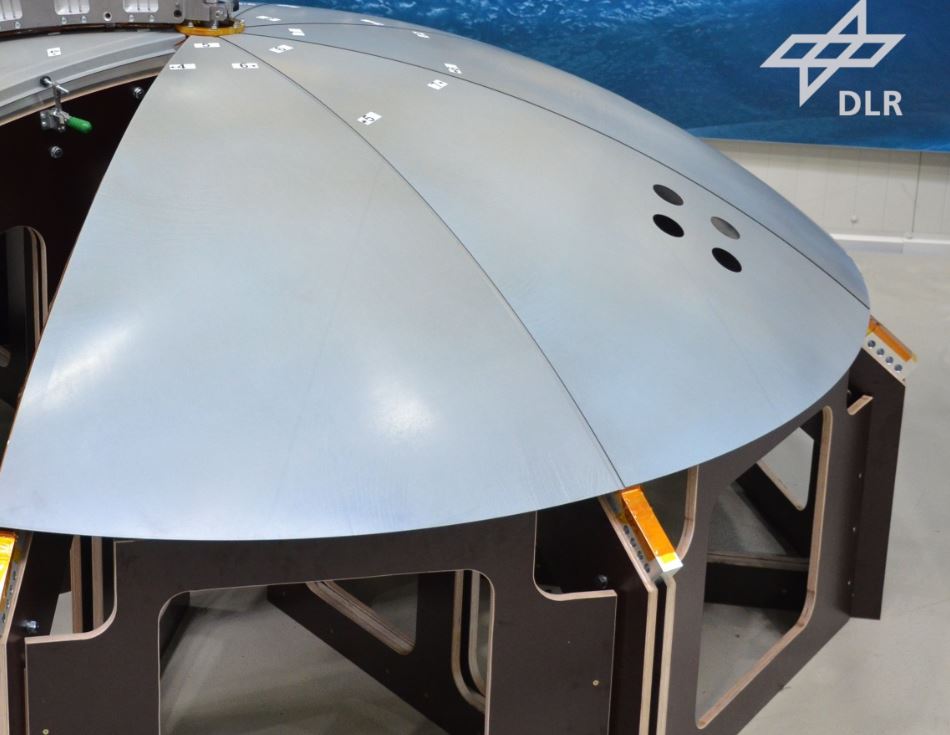

Thursday, 14 March 2019 | Integrated and automated production of a dry-fibre rear pressure bulkhead

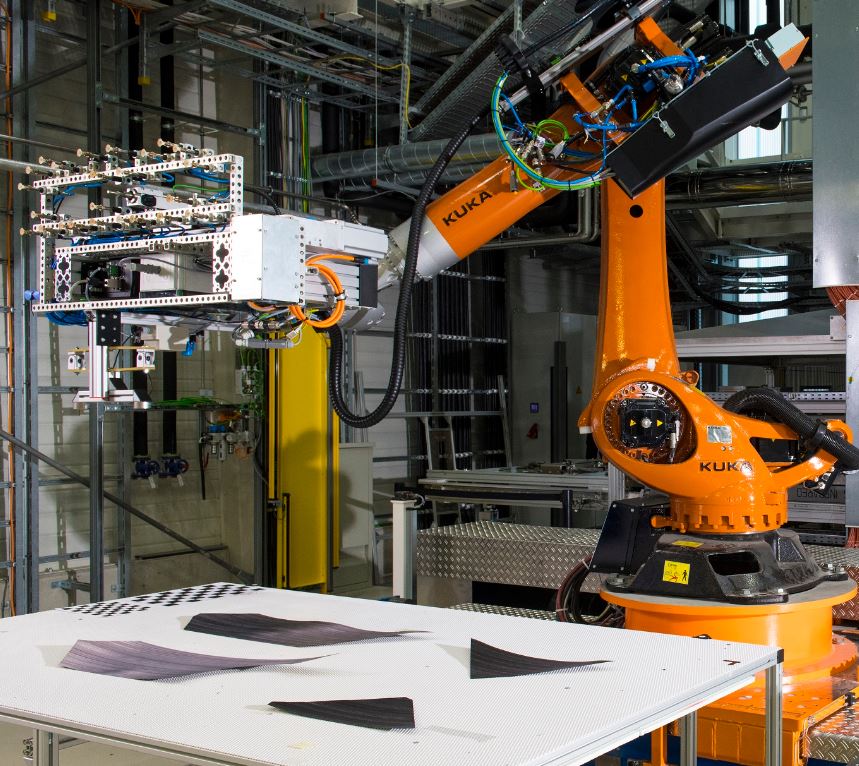

Within the PROTEC NSR project, the Center for Lightweight Production Technology (ZLP) in Augsburg develops an integrated manufacturing process for full-scale structural components such as a double-curved rear pressure bulkhead (4.5 metre diameter). The researchers recently succeeded in demonstrating an integrated VAP© vacuum-bagging process, enabled by an automated Pick-and-Place process. Using a flexible multikinematic gripper, 26 plies of varying geometries are positioned and fixed exactly. In addition, an automated dry fibre pick-and-place process with different gripper systems has been developed. This industrialised process combines the advantages of the respective single-step actions, reduces total manufacturing time, and enables a highly reproducible placing quality.

News 6

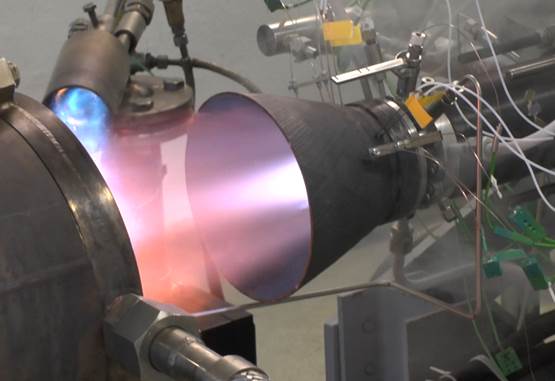

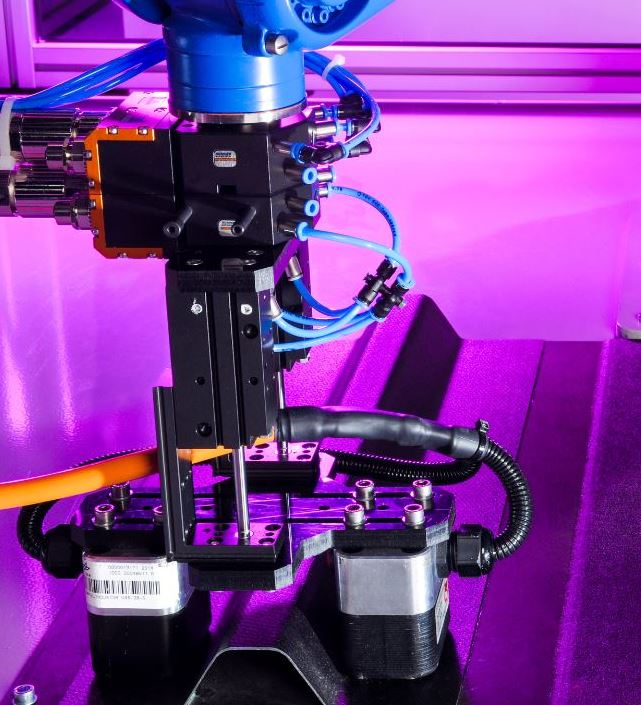

Thursday, 14 March 2019 | Thermoplastic Automated Tape Placement

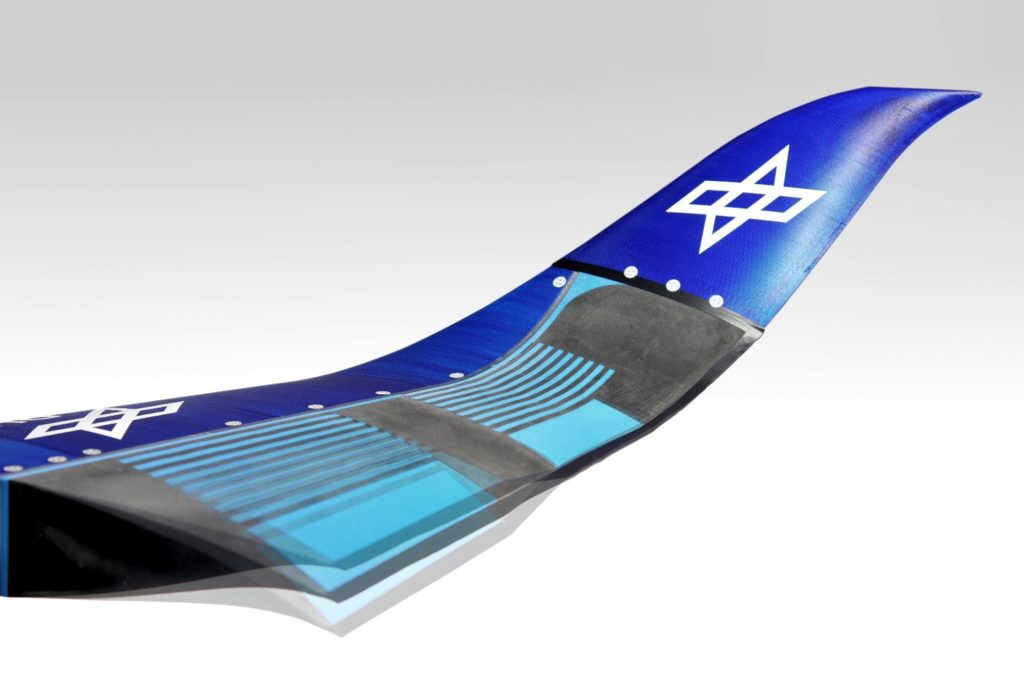

The Institute of Structures and Design develops laser-based in-situ tape placement for industrial application. Therefore, it features a state-of-the-art Automated Tape Placement (ATP) facility for the manufacturing of fibre-reinforced thermoplastic components. Working closely with fibre and thermoplastic tape suppliers, as well as industrial and academic researchers, innovative new parts for aeronautical, space, and automotive applications are developed.

News 5

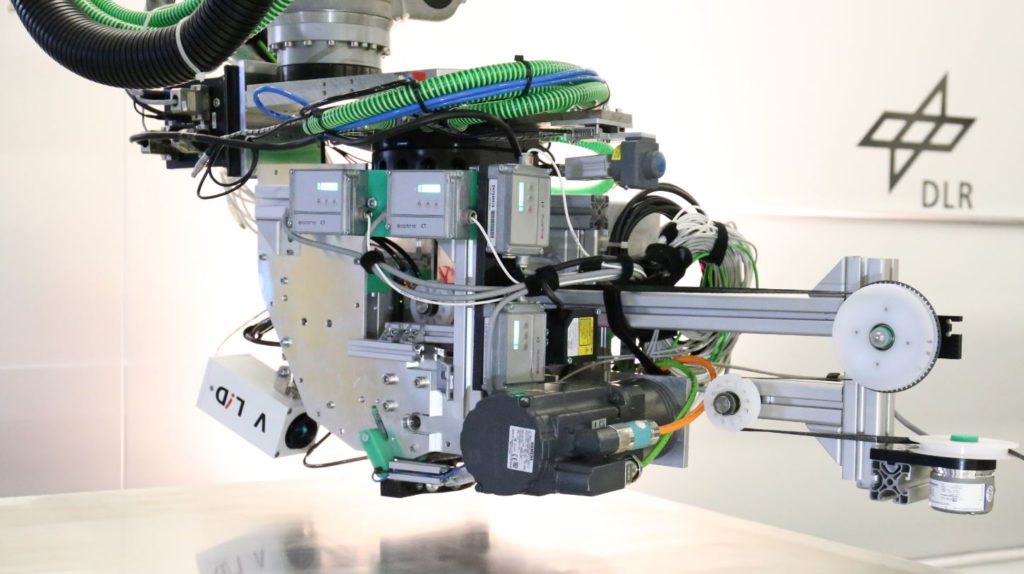

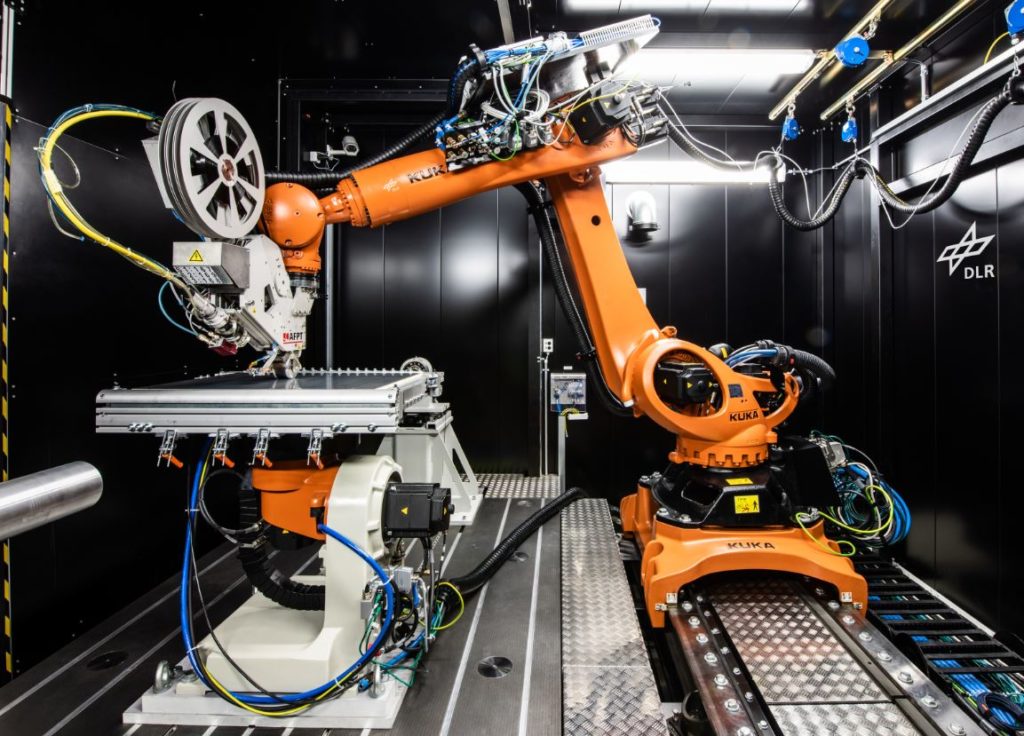

Thursday, 14 March 2019 | Robot-based Continuous Ultrasonic Welding

At the Center for Lightweight Production Technology (ZLP) in Augsburg a robot-based continuous ultrasonic welding system has been developed. Mounted on an industrial robot on a seven meter linear track, it allows the flexible machining of huge plane and double-curved structures. The functional efficiency has already been proven on various components such as a stiffened fuselage panel or a rear pressure bulkhead. For a robust process, the accuracy of the welding process was qualified via a laser tracker system which measures the position of the end-effector during the welding process. Furthermore, the real time process data acquisition records process parameters such as pressure or welding power. This data is used during the process for an in-line quality assurance.

News 2

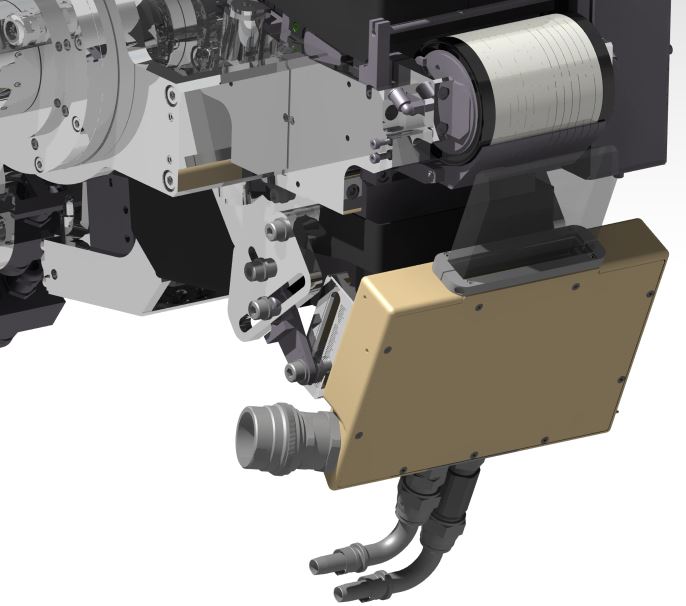

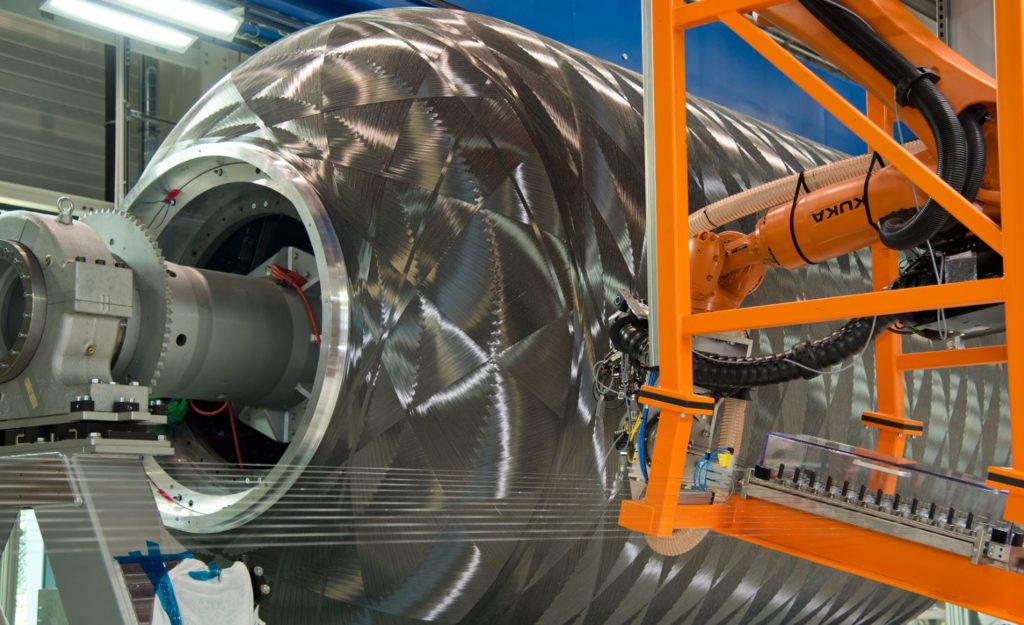

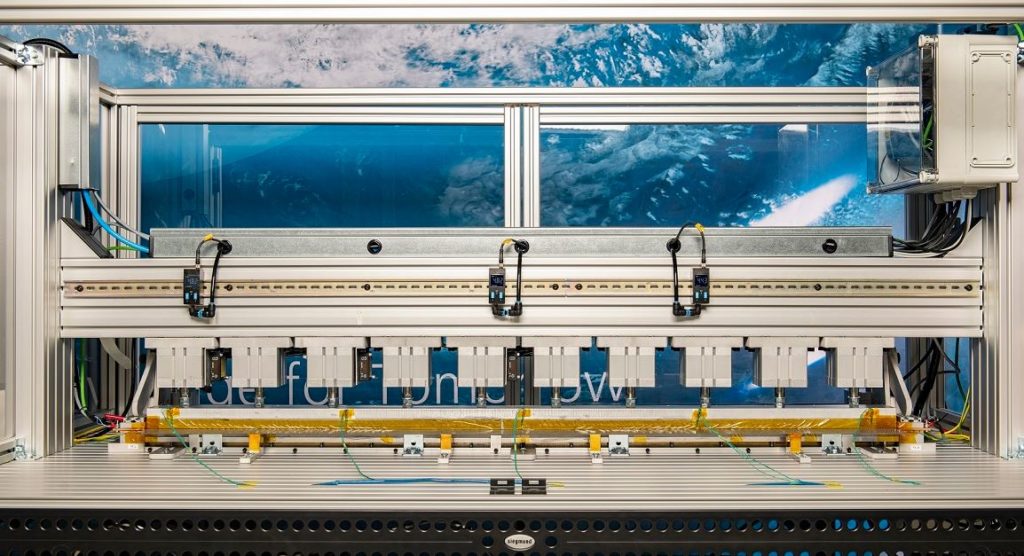

Tuesday, 12 March 2019 | World Premiere at JEC: DLR´s mobile layer unit

Novel mobile layup units can move around freely and lay the fibres directly in the mould. Several small, free-moving autonomous mobile layup units are expected to respond more flexibly than was previously the case to component scaling, geometry and design changes when used in a swarm, without rigid, limiting guidance kinematics. As there is no requirement to reinforce the facility’s foundations, the technology can be used within existing production halls. The use of mobile layup units in the production of large fibre-composite components is not limited to the field of aeronautics; another possible application is the production of wind turbine rotor blades. Since the mobile layup units can be deployed in such a flexible way, they could also be used to produce flat building components from fibre composites directly on construction sites.

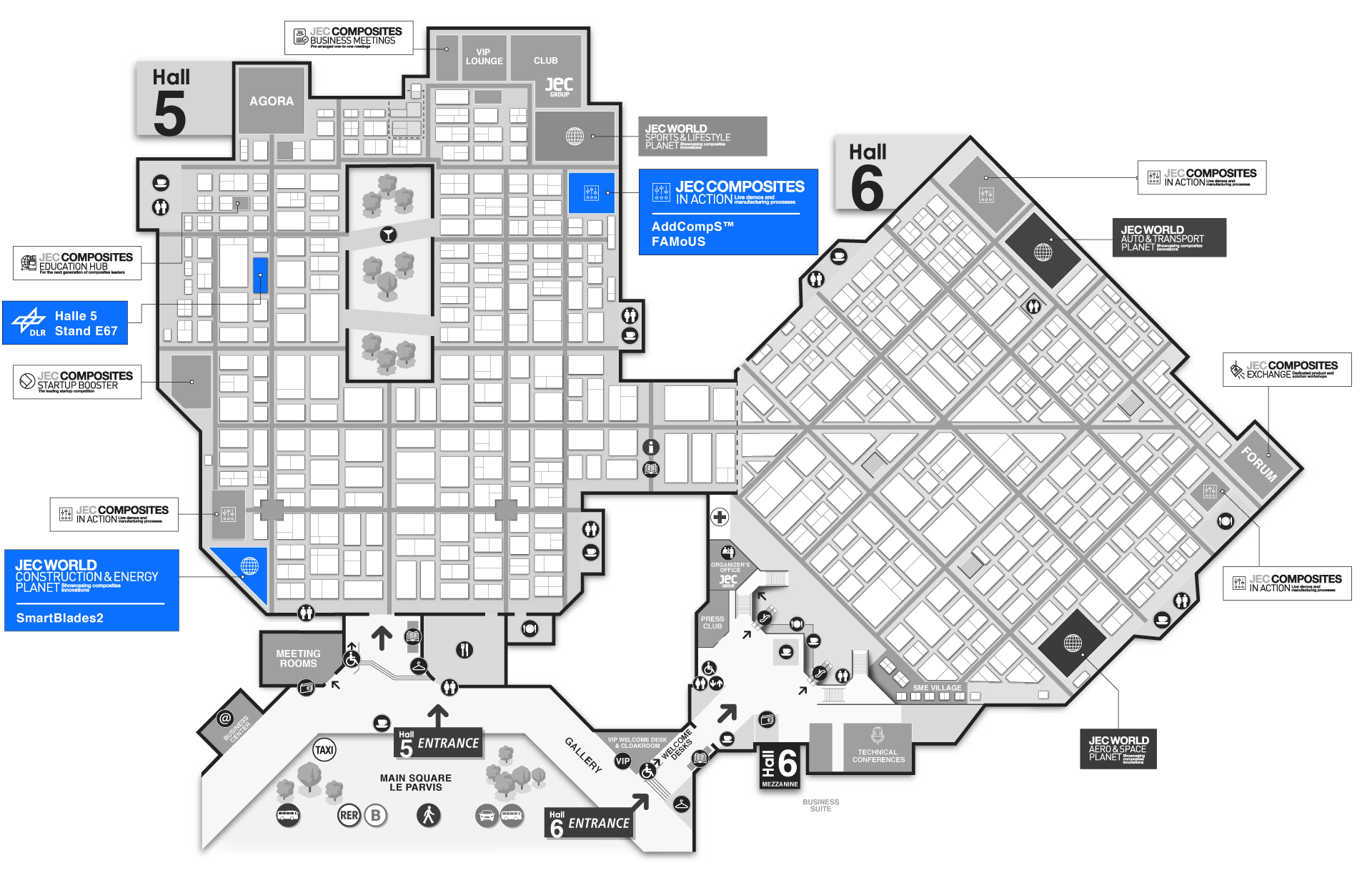

From 12 to 14 March 2019, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) will present current research projects in the field of high-performance fibre-reinforced plastics at JEC World in Paris, the leading European composites trade fair. This year, the joint presentation of the DLR Institute of Structures and Design, the DLR Institute of Composite Structures and Adaptive Systems and the Center for Lightweight Production Technology (ZLP), located in Augsburg and Stade, focuses on innovative technologies for the efficient production of composite fibre components. At the approximately 90-square-metre DLR stand, located in Hall 5 (E67), researchers will showcase and explain a wide range of applications, particularly in the field of aerospace.

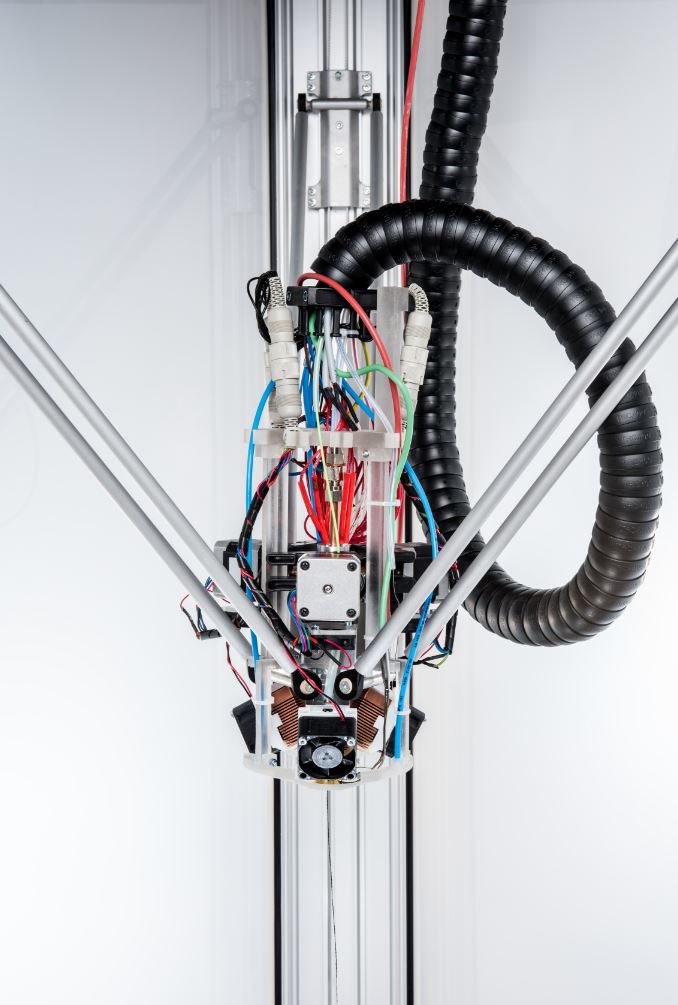

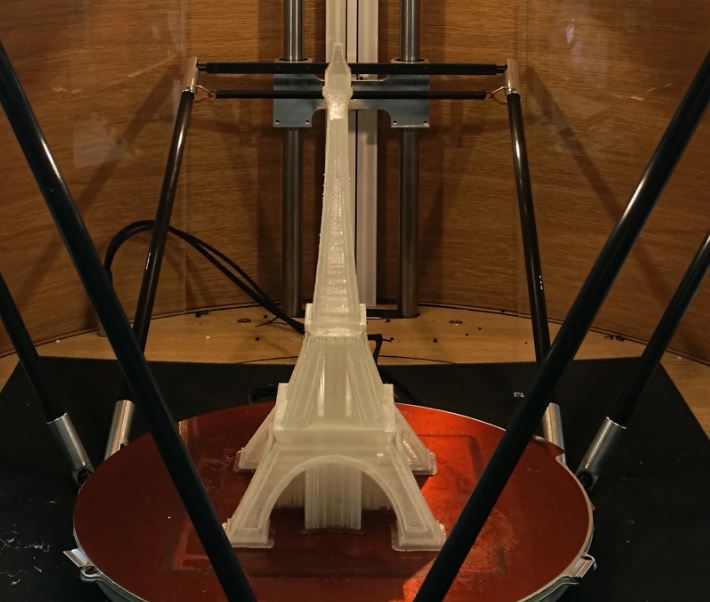

In addition, DLR will be represented in the area “Composites in Action – Additive Manufacturing” where it is going to introduce new methods for the 3D printing of fibre composites.

At the “Innovation Planet – Construction & Energy” area, DLR is going to showcase its results in wind energy research in the project SmartBlades2.

Contact

DLR Institute of Structures and Design: nicole.waibel@dlr.de

DLR Institute of Composite Structures and Adaptive Systems: jana.hoidis@dlr.de

DLR Event Management: michael.mueller@dlr.de

More information on the JEC World Website.