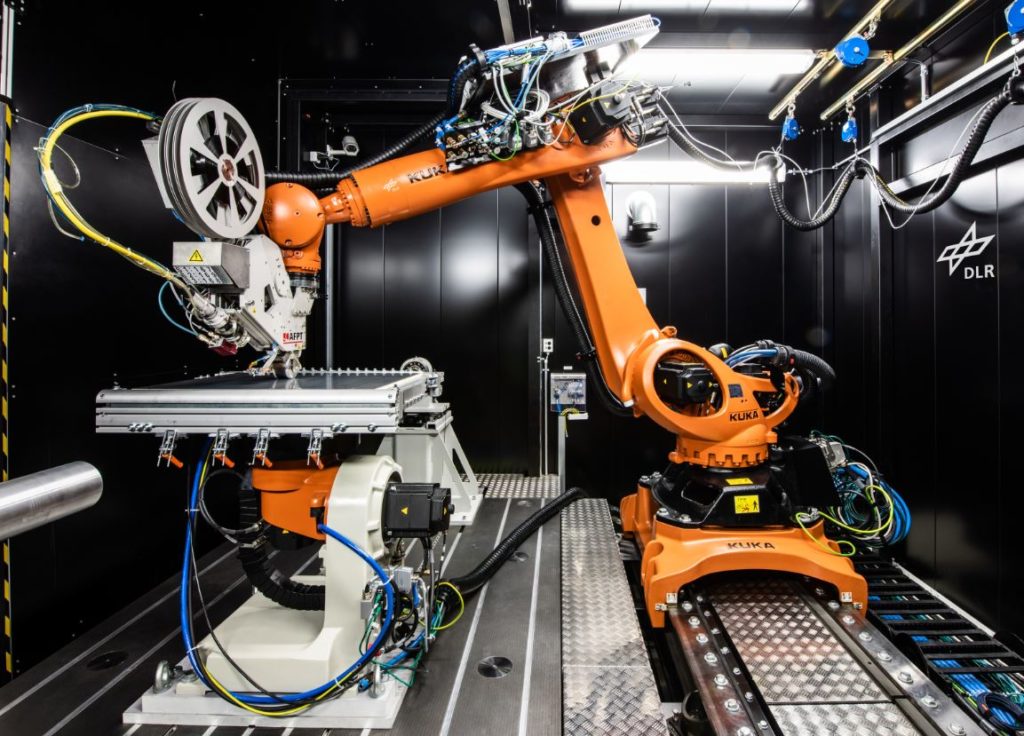

The DLR Institute of Structures and Design in Stuttgart features a state-of-the-art Automated Tape Placement (ATP) facility for manufacturing fibre-reinforced thermoplastic components. The Institute works closely with fibre and thermoplastic tape suppliers, as well as industrial and academic researchers, to develop innovative new parts for aeronautical, space, and automotive applications.

The ATP facility comprises:

- a six degree-of-freedom robot

- a rotating/winding axis

- a two degree-of-freedom (rotation and inclination) tool surface

- a single tape deposition head (tape width 6-25 mm)

- a multi-tape deposition head (3 × 13 mm tapes simultaneously).

This facility is able to produce components up to a maximum length of 3.6 metres and width of 2.0 metres. These parts range from flat and double-curved surfaces to cylinders and other axisymmetric shapes. The facility is also used to produce bespoke geometries for standard and novel material characterisation tests. The facility uses a six-kilowatt laser to heat deposited material to temperatures in excess of 420 degrees Celsius, allowing PEEK and other high-performance thermoplastics to be processed.

German Aerospace Center (DLR)

Institute of Structures and Design

Sebastian Nowotny · E-Mail: sebastian.nowotny@dlr.de · DLR.de