The development of an additive extrusion process for the production of thermoplastic, continuous fibre-reinforced free-form structures on the basis of in-situ impregnation enables the generation of high-performance components from low-cost, semi-finished products. This process allows highly-integrated, fibre-reinforced lightweight structures for future mobility applications to be produced efficiently.

AddCompSTM deals with the additive generation of multiscale, multimaterial, function-integrated, continuous fibre-reinforced structures. The ongoing work in the fields of process integration, materials development and characterisation, extrusion technology, quality assurance, simulation methodology and design methodology covers the entire additive extrusion process chain. The combination of technological developments with established manufacturing processes creates the basis for a new class of lightweight structures. Expensive tooling costs are avoided and complex, three-dimensional load path-oriented fibre reinforcements are easy to implement.

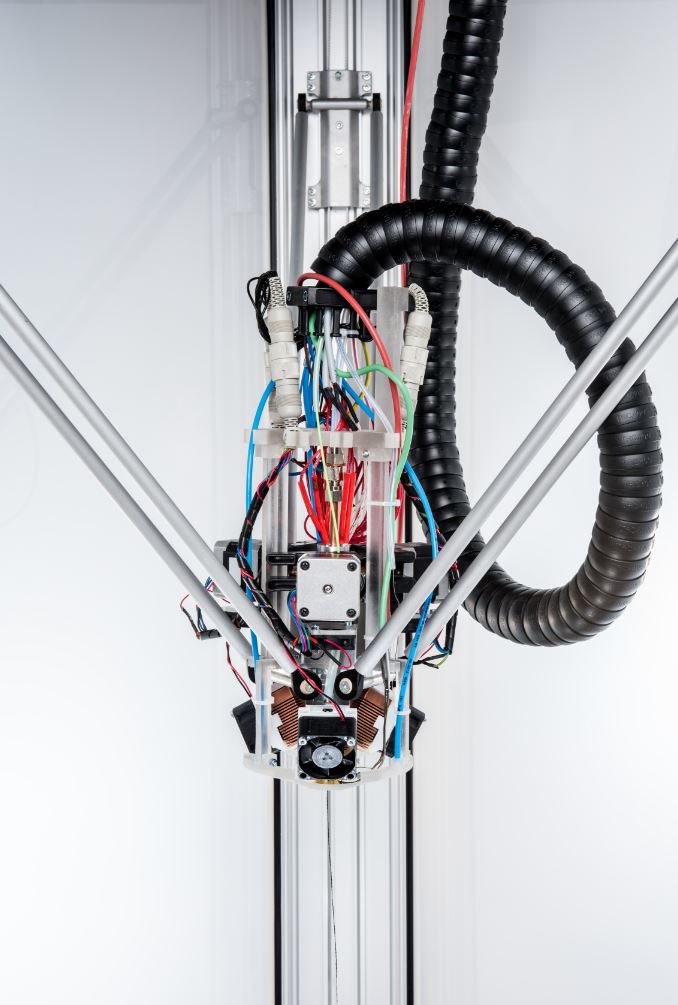

The novel additive extrusion technology developed by the DLR Institute of Composite Structures and Adaptive Systems is capable of processing standard thermoplastics (e.g. PLA, ABS, PA) as well as high-performance materials such as PEI or PEEK. Using this innovative process, 24K continuous fibre rovings are directly impregnated with the thermoplastic in the extrusion unit and the consolidated material is extruded. The in-situ processing of standard semi-finished products permits previously unattained cost efficiency and process agility. Due to the consistent miniaturisation of the process technology, it can be mounted on almost any robotic system. Thus, both small and large-format build volume can be realised. A comprehensive analysis of the material properties also guarantees precise knowledge of the mechanical properties of the additively generated components. Additively manufactured composite components made of ULTEMTM 1010, ULTEMTM 9085 and PEEK reinforced with 24K carbon fibre rovings and 24K hybrid yarns are being exhibited at JEC 2019.

German Aerospace Center (DLR)

Institute of Composite Structures and Adaptive Systems

Maik Titze · E-Mail: maik.titze@dlr.de · DLR.de