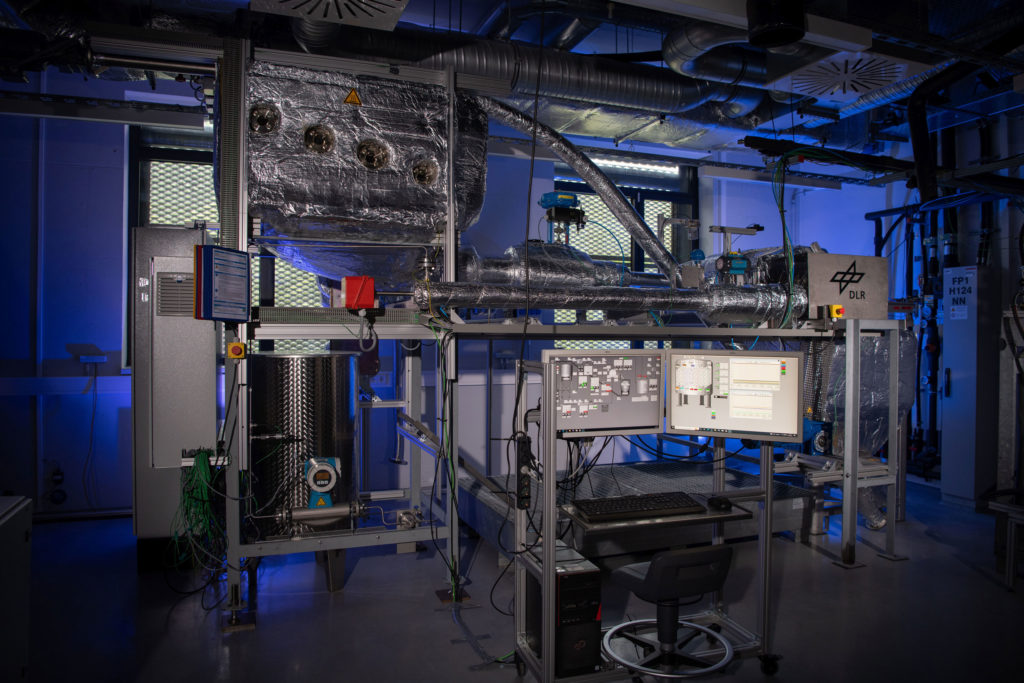

Active latent heat storage system

Fluctuating renewable energy sources, such as wind and solar power, are mainly used to generate electricity. However, over half of the energy demand is in the form of heat. Electrically charged thermal storage systems offer a solution by decoupling the heat demand from the availability of renewable electricity. Thermal storage systems are also often more economical than electrical storage systems and require fewer critical resources.

One method for storing energy as heat is through latent heat storage. This technology can store substantial amounts of thermal energy, releasing it as needed. It operates through the change from solid to liquid of a phase change material, with nitrate salts being an inexpensive and abundant option.

A potential application of latent heat storage lies in providing steam from renewable sources, particularly for temperatures ranging between 100 and 350 degrees Celsius. In this process, an electrical heating conductor melts the phase change material during charging, which is then stored in a ‘hot’ storage tank. During discharge, the phase change material solidifies on the surface of a specially designed heat exchanger. Given the poor heat conductivity of the material in its solid state, the heat exchanger requires either a significant surface area or the continuous removal of the material.

The exhibit from the DLR Institute of Engineering Thermodynamics shows the centrepiece of an active latent heat storage system: a model of the so-called rotating drum. During discharge, a liquid phase change material moves from a hot storage tank into a container beneath the drum. Inside the drum, the water evaporates, becoming available for industrial processes, while the phase change material solidifies on the drum’s exterior. The rotation of the drum and a scraper mechanism separate the solid material from the liquid, which then falls into a secondary ‘cold’ storage tank.

Link:

German Aerospace Center (DLR)

Institute of Engineering Thermodynamics

Dr. Jonas Tombrink · Email jonas.tombrink@dlr.de