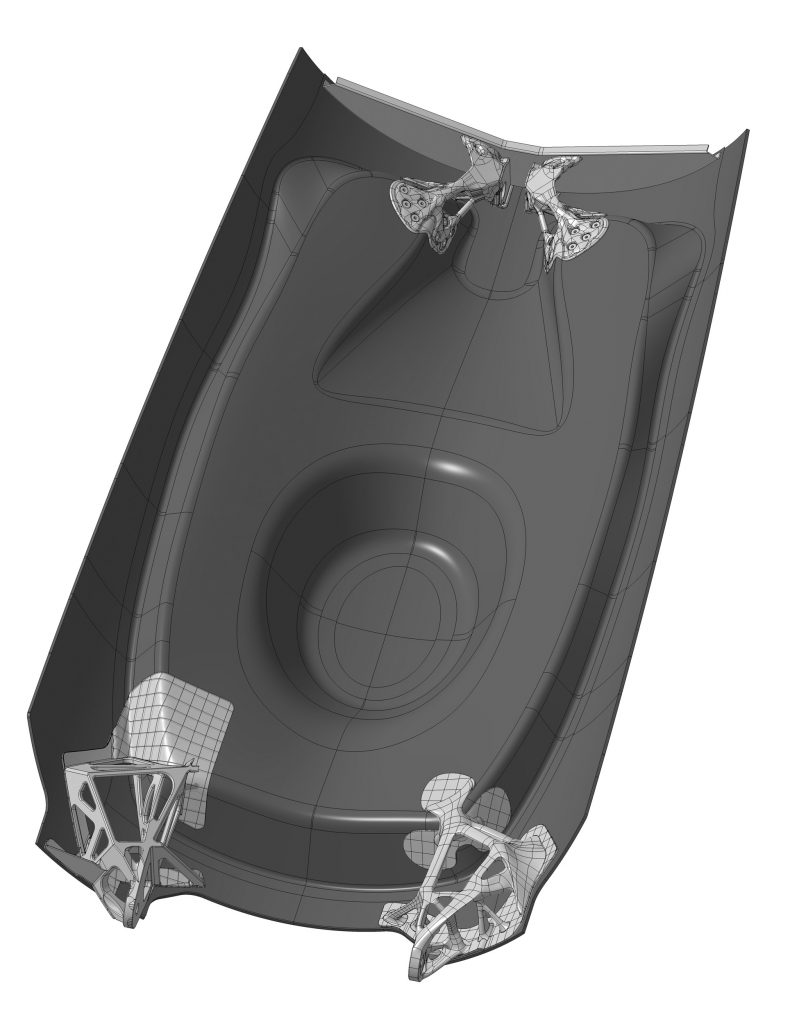

A demonstration of fbre-reinforced polymer-based designs for aviation

The airbrake demonstrator’s principal structure solely consists of two carbon-fibre reinforced polymer (CFRP) shells that are bonded together to carry the load. Innovative design and manufacturing methods were applied in order to distribute the load across the geometrically complex connecting surfaces. Optical mapping of the main structure and a topological optimisation process were used to design custom-fit mounts that offset geometric deviations in the composite fibre component. The hinge fittings were manufactured in aluminium precision casting using adaptive manufacturing models, while the actuator fittings were made from stainless steel by selective laser melting.

The demonstrator was implemented together with Airbus Defence and Space as part of the ‘Advanced Aerospace Structures’ project. This is a successful and long-term cooperation that also involves Airbus Central R & T and the Bundeswehr Research Institute for Materials, Fuels and Lubricants (WIWeB). The topics and strategy within the programme are closely coordinated with the German Ministry of Defence.

German Aerospace Center (DLR)

Michael Hanke · E-Mail: michael.hanke@dlr.de · DLR.de/en