Advanced thermoplastic composites are a highly promising candidate for future aerospace applications. In order to compete with metal-based solutions, highly effective and flexible production technologies are required. Weldability, in this context, is the key enabler for the successful introduction of thermoplastic composites into high-volume single-aisle programmes. This is particularly important because dustless assembly (without riveting and bolting) may allow a significant increase in the efficiency of major component assembly and final assembly lines. Technology readiness and robustness must be assured well in advance and first prove their feasibility at the component level.

Production and Assembly of Thermoplastic Composite Structures

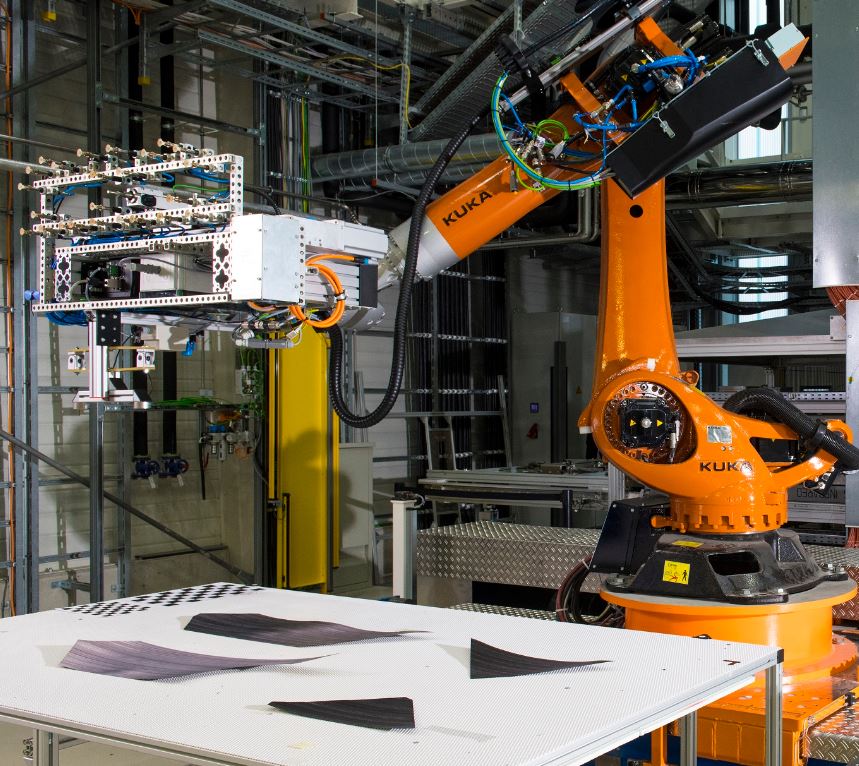

At the DLR Center for Lightweight Production Technology (ZLP) in Augsburg, an automated process chain for advanced thermoplastic composites from as-delivered material to component assembly has been set up within an integrated work cell. A smart manufacturing system is capable of handling tailor-made individually cut pieces that are stacked within curved moulds. The digital workflow connects all stages of production from component design through automated cut-piece fabrication, generation of system related meta-information, virtual planning of the pick and place process up to the final layup. Oven vacuum consolidation (VCT) was tested for final consolidation of the spotwelded laminate stack, i.e. processed out-of-autoclave (OoA).

Robot-based Continuous Ultrasonic Welding

As one of the most suited joining technologies, continuous ultrasonic welding is being developed and industrialised for robot-based assembly with a specially designed end-effector. Feasibility was demonstrated by welding thermoplastic stringers to a fuselage skin. Also, doubly curved structures such as rear pressure bulkheads may be joined using this flexible technology. Maturation and optimisation is supported by coupon testing and analysis of process data. The aim is to assure robustness through data-driven process control.

Active 3D-Thermo-Tomography for NDT

Each process step is evaluated by sensor-based in-line quality assurance and additional NDT where required. Apart from standard water-coupled ultrasonic inspection, thermography was applied for final non-destructive testing. As thermoplastic composites frequently contain a high number of intrinsic voids due to incomplete impregnation, active thermography as a non-contact testing method exhibits higher defect sensitivity, especially for thicker components. Evaluation has been performed based on a 3D thermo-tomography model with superimposed manufacturing and simulation data. This leads to a closed engineering loop and therefore a continuous improvement of manufacturing processes. The ZLP in Augsburg thus offers a wide range of technologies to render advanced thermoplastic composites ready for customised high-volume application.

German Aerospace Center (DLR)

Institute of Structures and Design

Dr. Ing. Frederic Fischer · E-Mail: frederic.fischer@dlr.de · DLR.de