Transpiration Cooled Ceramic High Performance Rocket Engines

Motivation and Design

- Improvement of high performance rocket engines

- Use of high temperature resistant and porous Ceramic Matrix Composites (CMC)

- High operation efficiency combined with transpiration cooling

- High operational reliability and damage tolerance

- Adaptation potential focussing several propulsion system cycles

- Light weight at high strength combined with CFRP housing

- Low fatigue caused by low thermal expansion structures

- Innovation potential for porous injection

- Optimization of the supersonic nozzle interface

- CMC/CFRP subsonic combustion chamber

- CMC injector: new design technology

- CMC supersonic nozzle extension.

Operational Requirements and Technological Approach

- Optimization of the supersonic nozzle interface

- Suitable material selections and coolant mass flow ratio‘s

- High temperature and thermochemical resistance at inner liner

- Natural micro-porosity of CMCs for coolant diffusion

- Adjustable coolant-permeability at CMCs

- Homogeneous coolant out-blow at inner surface

- Easy structural design and manufacturing

- Use of miscellaneous CMC properties at inner liner

- Thermochemical adaptation – stacking of mixed materials

- Diffusion adaptation – porosity defined by production process

- CMC densities: 2 – 3 g/cm3

- CFRP load shell – CTE » 6 × 10-6 1/K; densities 1.3 – 1.8 g/cm3

- Highly de-coupled structure principle; innovative interface technologies

- High degree of thermomechanical compatibility

- Established material quality management and reproducibility

- Spray optimization at porous injection

- Multi-shell design of the supersonic CMC nozzle extension.

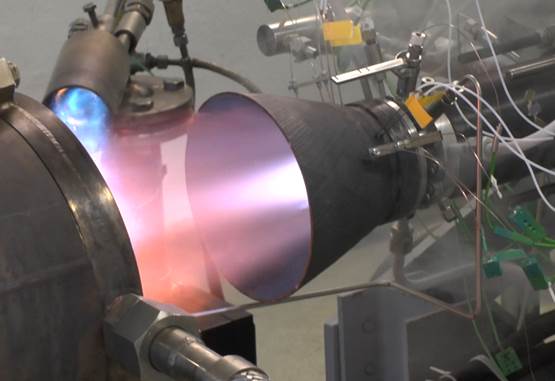

Technology Demonstration and Outlook

- Thermochemical resistant CMCs damage free operated

- High resilient CFRP-metal-interface proven & Cryogenic sealing technology reliable

- Extensive efforts on analytical and experimental basics

- Multiple high performance tests at

- European Research and Technology Test Facility P8

- Technology Test Bench P6.1

- TRL (Technology Readiness Level) of transpiration cooling: 5

- First promising P6.1 hot runs of the new injector concept

- First P6.1 proof tests of the partial double-shell nozzle design

- Full-scale 60 kN LOX/Methane demonstration at TRL 5

- Industry transfer / Licencing.

German Aerospace Center (DLR)

Institute of Structures and Design

Markus Ortelt · E-Mail: markus.ortelt@dlr.de · DLR.de